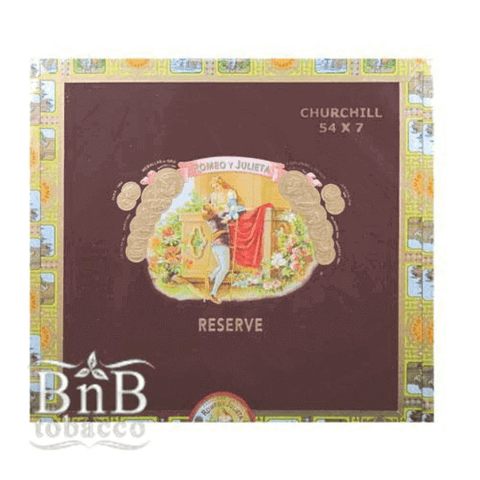

Everything You Need to Know About 'Reserve' Cigars Heading into 2026

The atmosphere in a room changes perceptibly when a smoker decides to bypass their daily rotation and reach for a premium cigar that bears the "Reserve" designation. It is a moment that signifies a shift from simple consumption to a reverent appreciation of agricultural artistry, a choice to engage with a product that represents the absolute pinnacle of patience and craft. This label serves as a quiet signal to the initiated, promising an experience that has survived a rigorous gauntlet of selection, fermentation, and aging that would have destroyed lesser leaves. When you hold such a cigar, you are not merely holding a roll of tobacco; you are holding a capsule of time, a preserved record of specific sunlight, soil chemistry, and human labor that has spanned years or even decades. The anticipation that builds before the flame is applied is rooted in the understanding that this is a finite experience, a fleeting opportunity to taste a blend that can never be truly duplicated once the stockpile is exhausted. It is an invitation to slow down the frantic pace of modern life and synchronize your breathing with the slow, deliberate burn of history.

Deciphering the Semantics of Scarcity

In the premium tobacco industry, language is often as important as the leaf itself, and few words carry as much weight—or as much potential for confusion—as "Reserve." Unlike the wine industry, which operates under strict governmental appellations that dictate exactly how long a Gran Reserva must age in oak barrels before bottling, the premium cigar world functions largely on an honor system. This lack of centralized regulation means that the term acts as a handshake agreement between the manufacturer and the consumer, a pledge of quality that is upheld by the brand’s reputation rather than international law.

The Manufacturer’s Pact with the Consumer

When a legacy manufacturer applies the reserve designation to a box, they are effectively staking their family name on the contents. This label is generally understood to mean that the tobacco used in the blend has been aged significantly longer than the standard production lines, often utilizing "vintage" crops from specific years that yielded exceptional harvests. It signals a departure from the recipe used for the core brand, moving toward a profile that highlights complexity, smoothness, and a distinct lack of aggression. The promise here is one of scarcity; because these blends rely on finite stockpiles of aged leaf, they cannot be mass-produced indefinitely, making every box a limited engagement with a specific moment in agricultural history. The consumer pays a premium not just for the materials, but for the assurance that the experience has been curated with a level of scrutiny that mass production simply cannot afford.

The Philosophy of Finite Existence

To truly understand the reserve category, one must distinguish it from the standard "production" cigar. A standard blend is an engineering marvel designed for consistency; the goal is for the cigar to taste exactly the same in 2030 as it did in 2020. To achieve this, blenders mix tobaccos from various years and farms to smooth out the inevitable variances of nature. A reserve cigar, however, embraces the unique characteristics of a specific crop or a specific aging process. It is less about uniformity across decades and more about the pinnacle of expression for that specific batch of tobacco. The smoker is trading the comfort of the known for the excitement of the exceptional, accepting that once the reserve of that specific leaf is gone, the experience can never be exactly replicated. This creates a psychological value for the smoker—the knowledge that the experience is fleeting adds a layer of appreciation to every draw.

The Agricultural Genesis of Elite Tobacco

The journey of a reserve cigar begins long before the seed touches the earth; it starts with the geology of the farm itself. While standard tobacco can be cultivated in a variety of environments with the aid of modern fertilizers, the leaf destined for a reserve blend requires a perfect storm of geological and climatic conditions. This concept, often referred to as terroir, dictates that the soil composition is the primary architect of flavor.

The difference between a harsh, biting smoke and a smooth, creamy reserve cigar is often found in the mineral composition of the dirt. Agricultural directors for premium brands treat their soil analysis with the rigor of a chemistry lab, understanding that the plant is merely a vessel for the nutrients available in the ground.

Reserve-quality tobacco is frequently grown in plots rich in magnesium. This element is critical because it promotes complete combustion. A cigar that burns completely yields a snow-white ash and, more importantly, prevents the buildup of carbon and tar that can sour the flavor profile. If the magnesium levels are too low, the potassium in the leaf cannot function effectively, leading to a jagged burn and a constant need for touch-ups with a lighter, which can overheat the tobacco.

Nitrogen and Flavor Profile

While nitrogen is essential for plant growth, an excess of it is disastrous for premium reserve tobacco. High nitrogen levels create large, lush, green leaves that look beautiful but taste coarse, metallic, and bitter. Growers aiming for reserve quality will often manipulate the soil nutrients to "starve" the plant of nitrogen late in the growing season. This biological stress forces the plant to stop growing vertically and focus its energy on survival, which results in the production of heavy oils and resins. These oils are the flavor reservoirs that will eventually develop into the complex notes of leather and spice during the aging process.

The Priming Hierarchy and Selection

A tobacco plant is harvested in stages, or "primings", working from the bottom up. Each level of the plant offers a distinct flavor and strength profile, and the selection process for reserve blends is notoriously draconian. Farmers must decide which leaves have the structural integrity and oil content to survive a decade of aging:

-

Volado (Bottom Leaves): These are high in combustion but low in flavor. While necessary for the burn, they are rarely the star of a reserve blend.

-

Seco (Middle Leaves): These provide the aroma and the bulk of the filler. For a reserve cigar, only Seco leaves with perfect texture are kept.

-

Ligero (Top Leaves): These leaves receive the most sunlight and are the strongest. Reserve blends often feature a higher percentage of Ligero to provide the body necessary to support long-term aging.

The Legend of Medio Tiempo

In very rare instances, a tobacco plant will sprout two small leaves at the very apex, above the Ligero. These are known as Medio Tiempo. They are small, thick, and incredibly potent, having absorbed the maximum amount of solar energy. Because they appear inconsistently—sometimes on only 10% of a crop—they are prized above all else. Many of the world’s most famous reserve cigars rely on these rare leaves to provide a depth of flavor that standard Ligero simply cannot match. The inclusion of Medio Tiempo in a blend provides a depth of flavor and a richness that standard leaves simply cannot achieve, offering a dense, chewy smoke that coats the palate.

The Fermentation and Curing Odyssey

Once harvested, the leaf is merely raw vegetation. The transformation into "brown gold" occurs during fermentation, a microbial process that is the single most defining factor in the quality of a reserve cigar. This is the stage where the raw potential of the field is tamed into the refined elegance of the humidor.

The Microbiology of the Pilon

Fermentation occurs when tobacco is stacked in large piles called pilones. The weight of the pile and the moisture within the leaves generate heat, activating bacteria that break down organic compounds. For mass-market cigars, this process is often accelerated to move product to the rolling tables quickly. For reserve tobacco, the process is deliberately retarded. The piles are monitored daily by the "patron" of the barn. If the temperature rises too high (often above 96 degrees Fahrenheit), the essential oils will evaporate, leaving the tobacco flat and tasteless. Reserve tobacco is turned frequently to keep the temperature lower, prolonging the fermentation cycle. A standard leaf might undergo one or two fermentation cycles, but reserve Ligero might undergo three or four cycles over a period of years. This exhaustive process ensures that every trace of impurity is processed out of the leaf.

The primary goal of this extended fermentation for reserve tobacco is the removal of harshness. Fresh tobacco contains proteins and carbohydrates that can taste grassy, bitter, or sharp. Through the extended fermentation reserved for elite leaves, these compounds are converted into simpler sugars and more complex aromatic compounds:

-

Ammonia Dissipation: Fresh tobacco is naturally laden with ammonia. If you have ever smoked a cigar that tasted sharp or caused the back of your throat to tingle, it was likely under-fermented. The extended fermentation used for reserve tobacco ensures that the ammonia is completely off-gassed.

-

Nicotine Reduction: This process also significantly reduces the nicotine content, meaning that a very dark, aged reserve cigar is often less physically intense than a lighter, younger cigar, allowing the smoker to focus on flavor rather than strength.

The Art of Aging: Beyond the Barn

If fermentation is the purification of the leaf, aging is its education. This is where the tobacco gains its sophistication and complexity. The term "Reserve" implies that this education has been equivalent to a doctorate rather than a high school diploma, involving years of dormancy where chemistry takes the lead.

Bale Aging vs. Barrel Aging

Most reserve tobacco continues to age in the bale. The pressure of the tightly packed leaves allows the tobacco to "marry," sharing oils and aromas within the bale. However, a niche subset of reserve cigars utilizes barrel aging. By placing the tobacco in barrels that previously held bourbon, rum, cognac, or sherry, blenders introduce a tertiary flavor component. The porous tobacco leaf absorbs the aromatic molecules trapped in the wood staves. The goal of barrel aging in a reserve program is subtlety. The cigar should not taste like a flavored product. The barrel notes should appear as a "ghost" flavor—a faint hint of oak or sweetness on the retro-hale that complements, rather than dominates, the natural tobacco profile.

The Phenomenon of Esterification

During these long years of storage—often five, ten, or fifteen years for the rarest leaves—a chemical reaction called esterification takes place. The residual acids in the tobacco react with the alcohols produced during fermentation to create esters. In organic chemistry, esters are the compounds responsible for fruit and flower aromas. This reaction is the reason an aged reserve cigar might possess notes of dried raisins, black cherries, or vanilla. These flavors are not additives; they are the result of time transforming the molecular structure of the leaf. It is a flavor profile that cannot be faked or rushed, serving as the chemical fingerprint of a true reserve. The longer the tobacco is allowed to rest, the more these esters develop, replacing the aggressive vegetal notes of youth with the refined, savory notes of age.

Construction and The Human Touch

You can have the finest, oldest tobacco in the world, but if it is constructed poorly, the experience is ruined. This is why reserve cigars are strictly the domain of the factory’s most elite workers, distinguishing them from the high-volume output of the main floor.

You see, the creation of a reserve blend is the responsibility of the Master Blender, a figure whose role is equal parts artist and historian. Unlike a chef who can buy fresh ingredients daily, a blender must work with the inventory on hand. When creating a reserve line, they are often trying to recreate a specific flavor profile using leaves that change slightly from crop to crop. They must taste the raw tobacco constantly, making micro-adjustments to the ratios of the filler leaves to ensure that the "Reserve" of the current year tastes consistent with the reputation of the brand, even if the components are slightly different from previous years. It is a high-stakes puzzle where a single misstep can ruin a production run worth hundreds of thousands of dollars.

Now, in every major factory, cigar rollers (torcedores) are graded by skill level. A novice might spend years making simple, short-filler cigars before touching premium long-filler. Reserve cigars are almost exclusively rolled by the highest grade of rollers—often designated as "Level 9" or "Grade A." These artisans have decades of experience and the tactile sensitivity to handle aged tobacco. Aged leaves are less elastic and more prone to tearing than fresh leaves. It takes a gentle, confident hand to stretch a ten-year-old wrapper leaf over a binder without cracking it.

Also, many reserve cigars utilize the entubado rolling method, considered the most difficult and time-consuming technique in the industry. Instead of folding the filler leaves together (a method known as "booking"), the roller rolls each individual filler leaf into a tiny tube before bunching them together. This creates dedicated airflow channels running the entire length of the cigar, and yields a draw that offers the perfect amount of resistance—not too loose, not too tight. It ensures that the smoke is delivered to the palate cool and flavorful. While this method drastically reduces the daily output of a roller, it is often a non-negotiable requirement for reserve-grade production.

What to Expect in Terms of a Sensory Experience

When a smoker lights a reserve cigar, they are often looking for a justification of the price point. That justification comes in the form of complexity, transition, and finish. It is not about hitting the palate with a sledgehammer but rather seducing it with nuance.

Anatomy of the Puff: The Thirds

A reserve cigar should take the smoker on a journey. It should not taste the same in the last inch as it did in the first. Experienced smokers break the experience down into "thirds," anticipating the evolution of the flavor profile:

-

The First Third: The experience often begins with a "greeting" of spice or toasted wood as the initial light settles. This is the waking up of the palate.

-

The Second Third: As the heat warms the oils further down the barrel, the profile should evolve. This is often where the benefits of aging shine, revealing notes of cream, nuts, caramel, or baking spices. The harshness should be non-existent.

-

The Final Third: A well-made reserve cigar should remain flavorful to the very end. While lesser cigars turn bitter and hot near the nub due to tar accumulation, a reserve cigar often deepens, offering a rich, savory finale that invites the smoker to burn it until it threatens the fingertips.

The Finish and Retro-hale

Perhaps the most telling sign of a reserve cigar is the finish—the aftertaste that lingers on the palate after the smoke is exhaled. High-quality, oil-rich tobacco leaves a long, pleasant finish. You should be able to taste the essence of the blend for minutes after setting the cigar down. If the flavor disappears instantly or leaves a metallic, acrid taste, the tobacco was likely not aged or fermented to reserve standards. Furthermore, to fully experience a reserve blend, one must retro-hale (pushing a small amount of smoke out through the nose). The olfactory sensors in the nose can detect floral and fruity notes that the tongue cannot. This technique unlocks the "hidden" dimensions of the reserve profile, revealing the delicate esters that were created during those long years in the bale.

Preservation and Custodianship

Once a reserve cigar leaves the shop, the responsibility for its preservation shifts to the consumer. These cigars are more sensitive than standard sticks and require attentive custodianship to maintain their peak condition.

While the standard rule for cigar storage is 70% relative humidity (RH), many collectors find this too high for aged reserve cigars. Aged tobacco is hygroscopic and can become "soggy" at 70%, leading to burn issues and muted flavors. Many serious collectors prefer to store their reserve stocks at a lower humidity, typically between 62% and 65%. This drier environment allows the cigar to burn cooler and cleaner, which is essential for unlocking the delicate esters formed during aging. If the cigar is too wet, the heat required to keep it lit will destroy the subtle flavor compounds.

For years, cigar lore held that a dusting of white powder on a cigar was "plume" or "bloom," a sign of crystallized oils and perfect aging. Modern scientific analysis has largely debunked this, revealing that nearly all instances of "plume" are actually microbial growth or mold. If you see white dust on your reserve cigar, inspect it closely. If it is fuzzy or three-dimensional, it is mold. If it wipes off easily and leaves no stain, it is likely harmless surface bacteria. True crystallization is microscopic and exceedingly rare, looking more like a glittery sheen than a dusty powder. It is always safer to wipe the cigar down with a dry cloth and lower the humidity in your storage unit rather than risking the health of the rest of your collection.

The Ritual of Consumption

Smoking a reserve cigar is not an act to be performed while mowing the lawn or rushing to a meeting. It requires a modification of the smoker’s usual habits to fully honor the product and extract the maximum enjoyment.

Cutting and Lighting Techniques

The wrapper of a vintage reserve cigar is a delicate membrane, often thinner and more fragile than current production leaves. A blunt cutter can crush the head of the cigar, causing the wrapper to unravel and ruining the draw. A sharp, double-guillotine cutter is the standard tool, but many aficionados prefer a V-cut for reserve cigars. The V-cut opens a deep channel for airflow without removing a large surface area of the cap, providing structural stability that helps the cigar hold together during the hour-long smoke. When lighting, a soft flame (matches or cedar spill) is preferable to a high-powered torch. The intense jet of a torch can scorch the foot, carbonizing the tobacco and ruining the first inch of flavor. Toasting the foot slowly with a soft flame ensures the oils are heated gently, preserving the delicate aromatics.

The Cadence of Smoking

The most common mistake made with reserve cigars is smoking too fast. Puffing frequently overheats the ember, turning the complex flavors into a monolithic bitterness. The ideal cadence is approximately one puff per minute. This slow pace keeps the cherry cool, ensuring that the smoke that reaches the palate is flavorful rather than hot. It also allows the finish to develop fully between draws. A reserve cigar is a conversation partner; it requires you to listen (taste) as much as you speak (puff). By rushing the experience, you negate the years of patience that went into creating the cigar in the first place.

The Legacy of the Leaf

The true value of a reserve cigar lies not in the gold embossing on the band or the prestige of the brand, but in the stillness it imposes upon the smoker. In a world defined by frantic speed and digital noise, these cigars stand as a defiant monument to the necessity of waiting. They serve as a tactile reminder that the most worthwhile things in life—whether a relationship, a skill, or a blend of tobacco—cannot be hacked or hurried; they must be nurtured through the slow, quiet passage of time. When you finally settle into a leather chair and watch the blue-gray smoke drift toward the ceiling, you are not just consuming a product; you are participating in a ritual of patience. The ash that grows long and steady is a measure of moments reclaimed from the chaos of the day, a fleeting but profound connection to the earth and the hands that tended it. It is this pause, this deliberate breath in a breathless world, that makes the reserve experience worth every penny.

← Older Post Newer Post →