What is Cigar Color Grading?

Cigar Pipe & Tobacco Guides cigars color grading stogies wrapper

In the cigar world, painstaking craftsmanship is rewarded and respected. As you probably know, every aspect of cigar manufacturing requires a magnificent attention to detail, and that’s why so many cigars are considered luxury items besides being enjoyable ways to pass the time. We all know the amount of effort that goes into acquiring the best tobacco, wrapping it perfectly and keeping it in the right conditions so that it can be satisfying when the smoker finally lights it. But, there’s another aspect to cigar manufacturing that might even be more time-consuming than the steps that we just described, and that’s color-grading.

Color-grading is relatively superficial compared to the other tasks that cigar workers are given, but it’s a timeless tradition that makes a difference, nonetheless. We’ll be explaining what color-grading is, why it matters and how it’s done so that you have an even stronger appreciation for the industry the next time you go into a cigar shop to pick out your next smoke.

Making the Grade

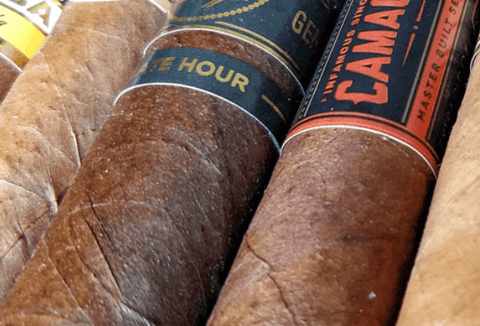

Color-grading is a time-consuming process that involves separating cigars according to the colors and shades of their wrappers. There are seven different color grades, and about 65 different shades total. Basically, the color-grader separates the cigars by eye, putting like shades together so that when the consumer looks at a shelf of cigars, they can see that they all match. The reason for this is superficial as it doesn’t actually affect the quality of the smoke. Rather, cigar aficionados enjoy having a collection of cigars that all match in terms of aesthetics.

Color-grading has been a practice since basically the beginning of the cigar industry, and to many, it’s a timeless tradition that has sentimental value as much as practical worth. The tedious nature of this process proves that the cigar industry is one of the last remaining industries that continues to do much of its work by hand, and because of this, cigar enthusiasts continue to appreciate the industry immensely.

What Does the Process Entail?

The process of color-grading is as laborious as it sounds. In order for each cigar to be separated with the utmost accuracy, it must be done by hand, or, rather, by eye. To most people, the subtle changes in shade are undetectable. That’s because the majority of people can only see a limited shade range. However, those who can see a wider spectrum of color are the ones who end up doing the job.

Unsurprisingly, it’s women who tend to be color-graders. Science has shown us that women can see a wider spectrum of color than men, and so they’re trusted with this extremely time-consuming job.

Once each cigar has been sorted according to its color and shade, it’s placed in a box with the matching ones so that they may be shipped off to a distributor. It’s up to the distributor to carefully keep all of the matching cigars together so that when they go on a shelf, a particularly discerning customer can tell that the cigars are properly separated according to color and shade.

Overall, Just Another Way to Identify Quality

Color-grading is an incredible time-consuming and laborious task that depends on superior vision to be executed. While most people will think that this step is unnecessary, real cigar enthusiasts appreciate the extra work that goes into it. So, the next time you go shopping for a cigar, pay careful attention to the shade of the wrapper.

← Older Post Newer Post →